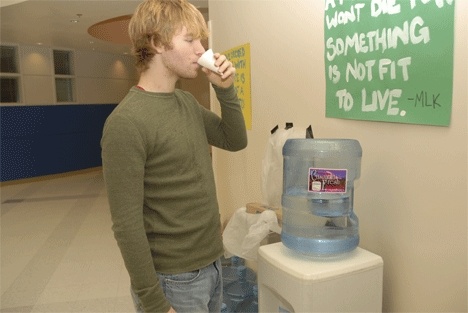

LANGLEY — Water coolers with full boxes of conical paper cups line the hallways of South Whidbey High School and sit next to water fountains covered with plastic.

For years now, the school district and parents have wondered why there was lead in the water and how long the students would have to drink bottled water.

The answer to the second question will come hopefully by the end of the school year, said district maintenance supervisor Joe Anastasi.

The school district is preparing to ask for bids from contractors to build an ozone water treatment system within the next week, said Anastasi.

“If we bid it next week, probably by the end of March, we could have a contractor in place and they can go in,” he said. “We’re asking for a 60-day construction period.”

That puts the completion of the building and installation of the water treatment system at around June 1, he said.

The Washington State Department of Health will then test the water for compliance with regulations and safety.

The district will have paid $150,000 of the nearly $600,000 price tag for the system after being awarded grants and loans to take care of the problem.

And that is not the only cost associated with finding a solution, Anastasi said.

The district has paid $50,000 per year for bottled water, as well.

“Right now the equipment is on site. The only cost now is getting the building constructed and installing the systems,” he said.

Anastasi is optimistic that the ozone system will work as advertised.

Initially, engineers thought a simple sand filter designed to remove iron and manganese from the water would be effective. The sand did not remove enough iron, however.

Engineers then discovered organic carbon mucking up the works, so a second system was investigated that would be designed to remove the carbon, but would have cost the district a lot of money for filters. That system was shelved.

The problem of lead in the water is a cause-and-effect issue, not a well-water issue, Anastasi said.

“What we have is very high iron concentrations, very high manganese concentrations, ammonia and hydrogen sulfide in the water,” he said. “And because we are on a well, we have to maintain a chlorine residual at the end-points of the line to kill any bacteria in the lines.”

Because the other contaminants in the water consume a large amount of chlorine, there is not enough left in the system to kill the bacteria. This forces the district to add more chlorine to the system.

And chlorine makes the water corrosive, which leaches lead out of the faucets in the school buildings along Maxwelton Road, Anastasi said.

The new system will attempt to remove the manganese, iron and organic carbons from the water by oxidizing it with ozone, reducing the need for high amounts of chlorine in the water.

“We go through 12 55-gallon barrels of chlorine a year,” he said. “That’s a lot of chlorine. The water will be less corrosive with the new system and we anticipate reduced leaching of lead.”

Once the system is installed and operating, the water quality will be monitored frequently.

But Anastasi has a contingency plan should the system not work.

“Our next recourse, if we can’t get the lead reduced, is we’ll replace all the faucets and drinking fountains. But the ozone system is accepted technology, though more complex because it is more aggressive as an oxidizer and so it takes a little more maintenance.”

Anastasi said a fix to the water quality problem is near.

“It’s been a challenge. I’ve got an engineering background, so to me, it’s a learning process. We’re ready,” he said.

Anastasi said the cost of construction and installation could run close to $200,000.

That money would pay for a no-frills, 35-foot-by-25-foot building, a concrete foundation, plus a concrete water retention tank and installation of the ready-made water treatment system.

Spencer Webster can be reached at 221-5300 or swebster@southwhidbey

record.com.